The CONDOR 225 is a medium/fast speed tube filler with a capacity to produce about 80,000 tubes per shift. This 4-head machine is the first linear-model tube filler in Subnil’s range.

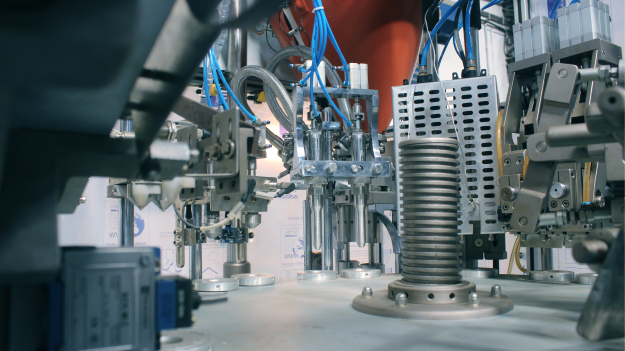

The tubes have to be first manually transferred from the tube box to the cassette provided on the machine. In turn the cassette transfers them, through multiple chutes, to a servo-driven pocketed conveyor. From the conveyor, multiple tubes are picked up by a rotary pick-up device, driven by servo, and loaded into the tube holders. First the tubes are centered & oriented and then filled. They are then closed depending on the type of tube.

In case of metal tubes, the tubes are flattened and crimped twice (or even thrice). In case of laminate / plastic tubes, they are first heated on the inside periphery and then sealed. Batch details are then coded on the crimp (or seal) with metal stereos and the tubes are ejected out either into a collection container or to a tube-transfer system to link to the downstream MERLIN 240XC cartoner from Vectacraft.