Products

View All Products

Explore and Learn

Tube Packaging Lines

Explore and Learn

SL35

Explore and Learn

SL70

Explore and Learn

SL100

Explore and Learn

SL150

Explore and Learn

SL225

Explore and Learn

SL300

Explore and Learn

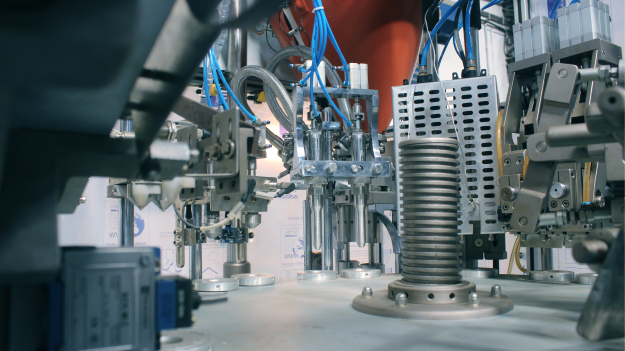

Tube Fillers

Explore and Learn

LIMBUS 35

Explore and Learn

LIMBUS 70

Explore and Learn

LIMBUS 100

Explore and Learn

LIMBUS 150

Explore and Learn

CONDOR 225

Explore and Learn

CONDOR 300

Explore and Learn